Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

-

Hey All! Lately there has been more and more scammers on the forum board. They register and replies to members requests for guns and/or parts or other things. The reply contains a gmail or hotmail address or similar ”anonymous” email addresses which they want you to reply to. DO NOT ANSWER ANY STRANGE MESSAGES! They often state something like this: ”Hello! Saw your post about purchasing a stock for a Safari. KnuckleheadBob has one. Email him at: [email protected]” If you receive any strange messages: Check the status of whoever message you. If they have no posts and signed up the same day or very recently, stay away. Same goes for other members they might refer to. Check them too and if they are long standing members, PM them and ask if the message is legit. Most likely it’s not. Then use the report function in each message or post so I can kick them out! Beware of anything that might seem fishy! And again, for all of you who registered your personal name as username, please contact me so I can change it to a more anonymous username. You’d be surprised of how much one can find out about a person from just a username on a forum such ad our! All the best! And be safe! Jim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ammunition integrity during firing process.

- Thread starter Devareaux

- Start date

- Status

- Not open for further replies.

Rick. I for one, am in agreement that this discussion is very interesting and helpful for most. Your 'Improving Accuracy' thread was very good. It was helpful for those that were getting into hand loading and wanted to learn how to do it right. It was also very helpful to show better ways of getting the best out of your firearm. I have the feeling that this discussion has drawn many who seem to want to exceed the possible performance capability of most factory bullet specifications. The basic fact is that all bullet manufacturers give performance guide lines for their products. These bullets are all designed for certain performance limitations and expectations. When hand loaders exceed the recommended loading data they should not look for reasons for failure other than their own fault. There are an infinite number of specific reasons that hand loading outside those limitations of the components will cause bad results. Hand loading is an enjoyable and rewarding experience if done with great care and good equipment. The components all come together to produce great accuracy and performance if common sense prevails.

There is an old cowboy saying- Never throw a $1500 saddle on a $50 horse. Hand loading requires good quality equipment, components, and judgement to avoid poor performance or damage. Sakojim.

There is an old cowboy saying- Never throw a $1500 saddle on a $50 horse. Hand loading requires good quality equipment, components, and judgement to avoid poor performance or damage. Sakojim.

icebear

Sako-addicted

Lugging the rifles to the range I proceeded to sight-in the little guys but as I recall the attempt was pretty frustrating. Put simply no hits on the target at 50 yards, 25 yards and at this point I got really frustrated. Moving down to the pistol range I finally got hits at 15 feet. I still have the targets with full longitudinal bullet profiles. It was obvious that the high velocity 17 caliber cartridges were causing the cores to destabilize resulting in unpredictably wild fliers.

I'm not sure that the problem was destabilization of the core. I've had lead pistol bullets tumble in midair at much lower velocities, and obviously with a solid lead bullet there's no core so you can't have core destablization. I'm much more inclined to think that in that case, the bullet was simply being driven to a higher velocity than that barrel and twist rate could stabilize it.

Speaking of core stability, or lack thereof, I once asked a police sniper why I was getting consistently lousy accuracy out of M855 62-grain "Green Tip" service rounds, even in heavy-barrel rifles that shot well with other ammo. This is a guy who has done a lot of weapon and ammo testing for accuracy. He told me that the penetrator core of these bullets was not consistently centered, and the variation caused the bullet to wobble. Acceptable in a battlefield situation where you're shooting full-auto; not so great for precision shooting.

And one final note - Metal does not have to melt completely to flow under pressure. Lead is a perfect example. You can squash a lead sinker or bullet with the relatively low pressure generated by a vise, or even a pair of pliers. This may or may not be relevant to any specific situation involving bullets at high velocity, but it's something to keep in mind.

Devareaux

Active Member

I'm not sure that the problem was destabilization of the core. I've had lead pistol bullets tumble in midair at much lower velocities, and obviously with a solid lead bullet there's no core so you can't have core destablization. I'm much more inclined to think that in that case, the bullet was simply being driven to a higher velocity than that barrel and twist rate could stabilize it.

Speaking of core stability, or lack thereof, I once asked a police sniper why I was getting consistently lousy accuracy out of M855 62-grain "Green Tip" service rounds, even in heavy-barrel rifles that shot well with other ammo. This is a guy who has done a lot of weapon and ammo testing for accuracy. He told me that the penetrator core of these bullets was not consistently centered, and the variation caused the bullet to wobble. Acceptable in a battlefield situation where you're shooting full-auto; not so great for precision shooting.

And one final note - Metal does not have to melt completely to flow under pressure. Lead is a perfect example. You can squash a lead sinker or bullet with the relatively low pressure generated by a vise, or even a pair of pliers. This may or may not be relevant to any specific situation involving bullets at high velocity, but it's something to keep in mind.

Very interesting information. It's good to keep in mind that lead indeed doesn't have to melt to flow under pressure, and also you mentioned that a police sniper commented on core bullets not being centered and it caused a wobble. This is very telling indeed, because all lead cores that usually have these integrity issues, and I'm speaking about rifle rounds here, are usually at high RPMs and that would make sense that integrity became a huge issue considering that the lead cores became off centered, especially if it's center of gravity shifted due to flow under pressure.

Thanks again for your input, because these tid bits of information really help when it comes to ammunition choices in our rifles, especially when on the hunt.

icebear

Sako-addicted

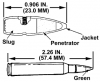

The sniper's comment was about the centering of the steel penetrator core in front of the lead slug, not the lead slug inside the jacket. The penetrator core doesn't drift off center during flight; it's not consistently centered in the first place. The latest M855A1 round doesn't use lead at all; the slug is a bismuth-tin alloy, making the new bullet somewhat longer because the alloy is less dense than lead. In any case, the previous comment referred to the old M855 cartridge. I haven't seen M855A1 ammo or bullets on the civilian market. The image below is the original M855.This is very telling indeed, because all lead cores that usually have these integrity issues,

Attachments

Last edited:

Devareaux

Active Member

All metals have a crystalline structure.

Dust is chunks.

The melting point of lead is around 600 °F.

Heat permeability in any metal is not high enough to transmit heat through the bullet body during the part of a second it takes the bullet to hit its target. Even less so when disintegrating mid flight.

Wound tracts are not cauterized.

Inferior jacket material does not lower the melting point of lead.

Well your assumptions on based on atmospheric pressures near sea level. Like I've stated before, lead doesn't need to reach 600F in a vacuum situation, or even in a near vacuum situation to flow. What you are saying is correct, but only if considering normal atmospheric conditions. Water will boil under a vacuum and then will actually start to freeze, so we must take into account that materials start acting very much different under certain pressures than it usually does at normal atmospheric conditions. Although I do understand what you mean as far as heat signatures, and maybe looking for cauterizing flesh to confirm a heat issue. Although what we're discussing is actually quite different and is happening under very extreme conditions and happening very fast and changing very fast.

Devareaux

Active Member

I think the OP has posted his theories & treatise on "Ammunition integrity" on the wrong forum. In all his extensive post the only time he used the word SAKO was in his greeting "Hello my fellow Sako members", except in post #15 where he made a brief reference to his Sako barrels. Not once has he mention a Sako rifle, model name, or asked a question about Sako or anything related to Sako. Then he proceeded to give his lengthy imaginings about bullet performance ad nauseam. There are forums where this subject matter can be debated that are much better suited to his crusade. This is the "Sako Collectors Club", not the bullet integrity club. I'm curious why he chose this site to espouse his theories while completely ignoring the subject of Sako rifles. I smell a troll!

First of all, I've not posted any of "my" theories. I said I had a hunch, a hypothesis, very different than a theory. Also, I posted manufacturers that have confirmed both plastic tips melting in ammunition, and also Erik over at Berger Bullets during his infamous "Bullet Failure Test". Secondly, this is the general discussion forum for SCC members, of which I happen to be one, and we're generally discussing ammunition integrity in rifle rounds, because I happen to be a proud owner of a Sako A-Series V long action, .30-06 1:10 twist ratio, 24" barrel with a breech diameter of 1.14 inches, muzzle OD diameter .629", with a sporter contour of the Hunter Variant, late 80's is my best guess, because of a solid recoil pad and the 578XXX SN. I would get a factory records search done for some verified information, but unfortunately I'm one of the members that own a later model A series V action Sako, and they don't have information regarding my rifle, much sad, much very sad.

There are posts in the general forum about Gun Shows and other non-related Sako information, and I don't see how you harass other members on their posts, and I don't understand why you would come and harass me on my post. My post is actually Sako related, because as we all know, you need good ammunition to fire down your Sako barrels, otherwise it's just a pipe with nice attachments. Thank you for your comments though.

Devareaux

Active Member

So, in order to extend some solutions in this thread, considering these problems as it pertains to lead core bullets and thin jacketed copper linings. So far the solutions I have found as far as ammunition is concerned are the Partition Bullets and the lead free Copper bullets. I put emphasis on 'so far' because these problems recently started cropping up for me, and I haven't tested a wide range of bullets as of yet. I'm sure there are some more thicker walled lead bullets that might operate just fine, and depending on twist rates and velocity and atmospheric conditions and whatnot, regular lead bullets work just fine in most situations. But I can't believe what I was seeing when they did not work in certain situations.

I have an 80's Sako barrel, it's a 24" 1:10 twist ratio, chambered in .30-06. I noticed that the newer Sako barrels are 1:11" twist ratios, so I'm glad I own the older model that I do, because the faster twist ratio works perfect for these longer copper bullets. I have only a limited stock of the copper bullets that I reserve for hunting only, because they are expensive but they sure get the job done. Because there are no lead cores, I've had very consistent results, even in a faster twist ratio, and because they retain so much of their mass, I've noticed that I've been able to take down game with smaller grain bullets than I have previously used, because so much more mass is present upon impact. The same is also true for these 'Partition' rounds. The front lead core is almost like a sacrificial bullet, because it always ends up disintegrating, but because there is the rearward lead core, expansion and mass retention assure that it gets the job done. I haven't recovered some of my other shots yet, and I'm hoping to see if these thicker copper jacketed bullets would also perform as well as the Partitions or the lead free Copper bullets.

Anywho, if you are like me, and you tend to recover your bullets when you are able to, to investigate them and to see the differences in various bullets, then I encourage you to post some of your information here at the Club, so that we can all benefit from the information with our rifles. I'm going to do some shopping soon, and I'll see if I cant get some more info and data on these various bullets. I really want to accumulate a good portion of evidence for these bullets that are failing under certain conditions. I have a good amount but I'll gather more and present it in time. Thanks everyone for your input, Godspeed.

I have an 80's Sako barrel, it's a 24" 1:10 twist ratio, chambered in .30-06. I noticed that the newer Sako barrels are 1:11" twist ratios, so I'm glad I own the older model that I do, because the faster twist ratio works perfect for these longer copper bullets. I have only a limited stock of the copper bullets that I reserve for hunting only, because they are expensive but they sure get the job done. Because there are no lead cores, I've had very consistent results, even in a faster twist ratio, and because they retain so much of their mass, I've noticed that I've been able to take down game with smaller grain bullets than I have previously used, because so much more mass is present upon impact. The same is also true for these 'Partition' rounds. The front lead core is almost like a sacrificial bullet, because it always ends up disintegrating, but because there is the rearward lead core, expansion and mass retention assure that it gets the job done. I haven't recovered some of my other shots yet, and I'm hoping to see if these thicker copper jacketed bullets would also perform as well as the Partitions or the lead free Copper bullets.

Anywho, if you are like me, and you tend to recover your bullets when you are able to, to investigate them and to see the differences in various bullets, then I encourage you to post some of your information here at the Club, so that we can all benefit from the information with our rifles. I'm going to do some shopping soon, and I'll see if I cant get some more info and data on these various bullets. I really want to accumulate a good portion of evidence for these bullets that are failing under certain conditions. I have a good amount but I'll gather more and present it in time. Thanks everyone for your input, Godspeed.

Devareaux

Active Member

The sniper's comment was about the centering of the steel penetrator core in front of the lead slug, not the lead slug inside the jacket. The penetrator core doesn't drift off center during flight; it's not consistently centered in the first place. The latest M855A1 round doesn't use lead at all; the slug is a bismuth-tin alloy, making the new bullet somewhat longer because the alloy is less dense than lead. In any case, the previous comment referred to the old M855 cartridge. I haven't seen M855A1 ammo or bullets on the civilian market. The image below is the original M855.

View attachment 23001

Very interesting. I'm only trying to picture in my mind's eye, a weight imbalance say on high rpm machine, and that causing it to wobble. So I'm thinking that if the lead were to soften and cause an imbalance due to shifting weight or center of gravity, that it might be causing issues in certain rifle bullets. Your comment about the steel core not being centered is what sparked that thought pattern. I apologize if I wasn't very clear in my words, I only meant to correlate what you were saying about the steel penetrators and the issues in the thread I was mentioning. Thanks for the information and the pictures, because it might come in handy later on.

CerebralDistortion

Well-Known Member

When you assume you make an ass out of you and me.Well your assumptions on based on atmospheric pressures near sea level. Like I've stated before, lead doesn't need to reach 600F in a vacuum situation, or even in a near vacuum situation to flow. What you are saying is correct, but only if considering normal atmospheric conditions. Water will boil under a vacuum and then will actually start to freeze, so we must take into account that materials start acting very much different under certain pressures than it usually does at normal atmospheric conditions. Although I do understand what you mean as far as heat signatures, and maybe looking for cauterizing flesh to confirm a heat issue. Although what we're discussing is actually quite different and is happening under very extreme conditions and happening very fast and changing very fast.

I do not assume.

You are mixing temperature and preassure.

Boiling is a non specific term describing a process where by water turns from one aggregate state to another due to increased energy level.

"Boiling" in vacuum is due to dispersion of water molecules in said absence of matter.

Water vapour does not turn solid in vacuum above its melting point.

You are really just hypothesizing and you are way off...

Devareaux

Active Member

When you assume you make an ass out of you and me.

I do not assume.

You are mixing temperature and preassure.

Boiling is a non specific term describing a process where by water turns from one aggregate state to another due to increased energy level.

"Boiling" in vacuum is due to dispersion of water molecules in said absence of matter.

Water vapour does not turn solid in vacuum above its melting point.

You are really just hypothesizing and you are way off...

Have you heard of a diesel engine before? It ignites it's fuel by utilizing pressure. This has to do with the 'Ideal Gas Law'

PV=nRT.

Modern bullets have higher BC, some have high SG, all of them a have higher velocities, and when you take into account higher velocities and faster twist rates, you get faster RPMs.

Now when you consider all of this with high BC bullets that tend to create a vacuum during travel, things start to get real weird, real fast. I think every case of disintegrating/vaporizing bullets are happening in the high BC bullets, and the only difference between lower and high BC bullets, is the vacuum that's created.

Water will boil in a vacuum, and it will also freeze.

Since you have nothing to add to the conversation, other than criticize someone for bringing up a very real situation within rifle shooting, I guess we'll just end this back and forth here.

paulsonconstruction

Sako-addicted

Please!!!I guess we'll just end this back and forth here.

kevinlg

Sako-addicted

My two cents worth. Up until now the only time I confirmed that the lead core was melting was when I goy my first 17 rifle. Actually I should say two of them. The first was a Rem 700 BD in 17 Rem and the second being a H&R Ultra wildcat in 17-223. I still have both by the way. All of this said back in the day I handloaded using Hornady 25 gr HP pills.

Lugging the rifles to the range I proceeded to sight-in the little guys but as I recall the attempt was pretty frustrating. Put simply no hits on the target at 50 yards, 25 yards and at this point I got really frustrated. Moving down to the pistol range I finally got hits at 15 feet. I still have the targets with full longitudinal bullet profiles. It was obvious that the high velocity 17 caliber cartridges were causing the cores to destabilize resulting in unpredictably wild fliers.

The solution came with the Remington 25 gr core lokt 17 caliber bullets. I recall that I had to buy a very large quantity of them to get Remington to sell the little buggers to me. I still have a bunch of them but I can tell you that hitting a fly on the target at 100 yards was something that I could do consistently.

rick

May I suggest a more likely cause was a severely fouled/coppered bore.....since I've never seen one of the old Hornady 25HP bullets fail to make it to the target through a CLEAN bore. They have long been a favorite among coyote hunters.

Years ago a friend brought over an H&R 17-223 that I had earlier sold him......saying it had "quit" shooting. Sure enough, it took 3 bronze brushes and about 2 hours(this was long before Wipe-Out).....to get the bore clean. Note that I try NOT to use JB Bore Cleaner on 17 caliber bores, since the land height is only 0.002"......AND, depending on the backing, JB's can prematurely wear the throat and change the bore's surface finish. These days I lean towards Wipe-Out.....Shooter's Choice w/Kroil......bronze brushes......and a small amount of Iosso Cleaner at the finish. Store with a bore coating of Lock-Ease.

Hope this helps.

CerebralDistortion

Well-Known Member

Yes, putting water in a freezer, albeit an inverted one, does tend to freeze it.

PV=nRT you know...

Having kept the temperature of the water up it would have evaporated, hence the salt at the bottom of the chamber.

The remaing water is freezing because the evaporation removes heat in the process. Not because of the vacuum.

There is a difference in definition here and it's important. Especially if you want to contend that lead goes from solid to molten due to the gyrational forces created in a rifle barrel.

All metals, well most anyway (quicksilver and some others behave differently) also has the property of shearing under force. It doesn't melt, it cracks.

The high BC bullets you are referring to are almost exclusively JHP. The same pressure that is melting the polymer tip is at the same time the vacuum affecting the lead inside the jacket melting it?

Chuck it. I cant be bothered to further comment on this farce of physics exploration...

PV=nRT you know...

Having kept the temperature of the water up it would have evaporated, hence the salt at the bottom of the chamber.

The remaing water is freezing because the evaporation removes heat in the process. Not because of the vacuum.

There is a difference in definition here and it's important. Especially if you want to contend that lead goes from solid to molten due to the gyrational forces created in a rifle barrel.

All metals, well most anyway (quicksilver and some others behave differently) also has the property of shearing under force. It doesn't melt, it cracks.

The high BC bullets you are referring to are almost exclusively JHP. The same pressure that is melting the polymer tip is at the same time the vacuum affecting the lead inside the jacket melting it?

Chuck it. I cant be bothered to further comment on this farce of physics exploration...

bloorooster

The Old Hippie

Kevin, are you saying to mix Shooters Choice and Kroil together, or is there a product of the two combined that can be purchased? I’ve used Shooters Choice for many years with wonderful results. Kroil on the other hand , I’ve only used as a penetrating solvent in mechanics and construction applications. I fear it with gun cleaning uses because it will melt certain plastics , polymers and non-metal surfaces (stock treatments like lacquer or varnish)

To the rest the of this controversial conversation, I must say I personally don’t have any degree of scientific knowledge to argue the points of physics and metallurgical properties. I can see where it has to apply in relation to projectile integrity, especially concerning small bore applications.

If a 25 g , . 17 caliber bullet with a jacket of copper with a thickness of say... .005”s, is pushed through a barrel with rifling that is .002” high. It will only leave approximately.003” +- of jacket material after it leaves the muzzle. Those grooves, in the jacket being thinner now are a weak point at each location around the entire circumference of the bullet. With Velocity reaching towards or past the 5000 FPS mark and the physical properties involved with aerodynamics and two different soft metals wrapped around each other, with the jacket now being compromised with grooves that thin it in multiple striations in its circumference, something has to give as those limitations are exceeded. The bullet, simply put is overwhelmed by the laws of physics.

Boiling points, vacuums , and mathematical algorithms can of course apply to all this, if we care to open our minds to it. OR, each of us can take what we care to take from it to apply to our own concepts or misconceptions.

I don’t think my bullets melt and fly apart in flight, but I don’t shoot .17 cal rifles either. I have heard of .25-06 pills (90g hp’s) exploding before they reach the ground hog 300 yards away simply because the bullet hit a blade of straw grass on its way there. Simple layman’s science.

Hippie

To the rest the of this controversial conversation, I must say I personally don’t have any degree of scientific knowledge to argue the points of physics and metallurgical properties. I can see where it has to apply in relation to projectile integrity, especially concerning small bore applications.

If a 25 g , . 17 caliber bullet with a jacket of copper with a thickness of say... .005”s, is pushed through a barrel with rifling that is .002” high. It will only leave approximately.003” +- of jacket material after it leaves the muzzle. Those grooves, in the jacket being thinner now are a weak point at each location around the entire circumference of the bullet. With Velocity reaching towards or past the 5000 FPS mark and the physical properties involved with aerodynamics and two different soft metals wrapped around each other, with the jacket now being compromised with grooves that thin it in multiple striations in its circumference, something has to give as those limitations are exceeded. The bullet, simply put is overwhelmed by the laws of physics.

Boiling points, vacuums , and mathematical algorithms can of course apply to all this, if we care to open our minds to it. OR, each of us can take what we care to take from it to apply to our own concepts or misconceptions.

I don’t think my bullets melt and fly apart in flight, but I don’t shoot .17 cal rifles either. I have heard of .25-06 pills (90g hp’s) exploding before they reach the ground hog 300 yards away simply because the bullet hit a blade of straw grass on its way there. Simple layman’s science.

Hippie

Last edited by a moderator:

Hippie. I can say only one thing. It is a shame that some folks try to find a scientific explanation for failure of a bullet when the simple explanation is caused by hot loading way beyond the designed specifications of the bullets use.

Your post was right on and I hope this ends the discussion. It serves as a learning lesson to hot loaders- expect problems. Period. Sakojim.

Your post was right on and I hope this ends the discussion. It serves as a learning lesson to hot loaders- expect problems. Period. Sakojim.

D

Deleted member 14372

Guest

So which commercial cartridges do we avoid? One of my rifles really likes PPU but it’s pretty cheap. How do I know if the bullets are no good or should I assume it?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

bloorooster

The Old Hippie

Lol!

None of it Dad! Try it all out, see what shoots best, like we’ve always done. Commercial Ammo cheap or not cheap. But if you handload, and you push the envelope to extremes to find that level of performance that dreams are made of.. there will be variables and pitfalls along the way.

Tight groups are what we all want, and almost every Sako I’ve owned produce them with fairly little effort in as far as what commercial ammunition is used. Some better some worse. It’s fairly easy to hand load within referenced parameters and tighten things up even more so with some time and experiment. It’s not rocket science really... but it’s not for mad scientists either.

The old Hippie

None of it Dad! Try it all out, see what shoots best, like we’ve always done. Commercial Ammo cheap or not cheap. But if you handload, and you push the envelope to extremes to find that level of performance that dreams are made of.. there will be variables and pitfalls along the way.

Tight groups are what we all want, and almost every Sako I’ve owned produce them with fairly little effort in as far as what commercial ammunition is used. Some better some worse. It’s fairly easy to hand load within referenced parameters and tighten things up even more so with some time and experiment. It’s not rocket science really... but it’s not for mad scientists either.

The old Hippie

D

Deleted member 14372

Guest

Ok. Getting into reloading now anyway.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

tilleyman

Well-Known Member

If a 25 g , . 17 caliber bullet with a jacket of copper with a thickness of say... .005”s, is pushed through a barrel with rifling that is .002” high. It will only leave approximately.003” +- of jacket material after it leaves the muzzle. Those grooves, in the jacket being thinner now are a weak point at each location around the entire circumference of the bullet. With Velocity reaching towards or past the 5000 FPS mark and the physical properties involved with aerodynamics and two different soft metals wrapped around each other, with the jacket now being compromised with grooves that thin it in multiple striations in its circumference, something has to give as those limitations are exceeded. The bullet, simply put is overwhelmed by the laws of physics.

Hippie

While I agree that the rifling engagement swage marks create weak points that can start stress risers and premature failure at elevated rpm, 17 cal bullets have a much thicker jacket than .005"... more in the range of .020" to .050".

There is some variation between brands and types (as expected, varmint bullets usually have noticeably thinner jackets) but there is also quite a lot of variation in the size and consistency of the lead core, the recess for the plastic tip, and the plastic tip itself.

When sectioning 17 cal 20gr bullets this was immediately apparent... what was also surprising was the presence of small voids in the plastic tips due to uneven cooling in the manufacturing process. When fired at 4,000fps (and spun at 320,000rpm) I'm sure these voids could easily be the cause of unexpected fliers or variable accuracy between batches of the same manufacturer's bullet.

Last edited:

- Status

- Not open for further replies.