"Sako TAPERED Dovetails".

They are tapered for a reason -- to assure that the recoil of the rifle when fired tends to make the scope mounts/bases tighter rather than tend to loosen them. This is a clever system which is unique to Sako (a few other manufacturers used integral dovetails, but they utilized cross pins or other mechanisms to keep the scope from drifting forward under recoil.)

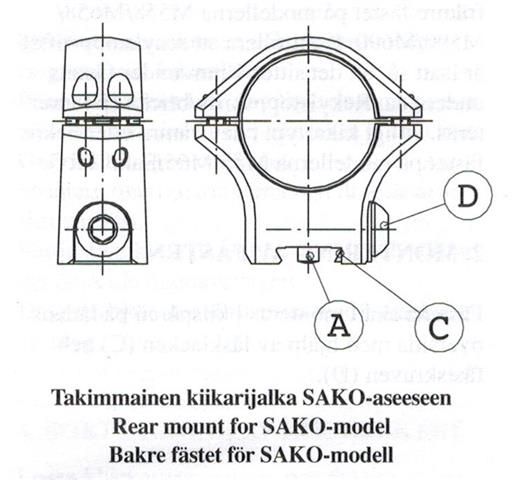

However, the tapering has one drawback: If the scope mount has one fixed claw (usually on the left side like Optilocks, Leupolds, etc.), then as the mount is positioned further forward on the dovetail the ring moves further to the left. If the front and rear rings are not positioned relatively close to the same place (fore and aft) on each dovetail, then the scope will point slightly left or right of the bore.

If in boresighting with the scope near its mid-range of adjustment the scope is pointing left, then this can be cured by either moving the rear ring forward or the front ring rearward (whichever is more practical). The opposite movement will compensate for a right-pointing scope.

In some applications, like a short scope on a long action, the latitude for movement of the rings may not be sufficient. If another type of ring which doesn't feature this problem (Millett, original Sako, Redfield, etc.) can't be substituted, then the proper ring (front or rear, according to which way the scope is off) can be modified with a three-corner file by slightly widening its clamp groove. This will have the same effect as "moving" that particular ring rearward, so be sure which way it is that you want your scope to move.

Having never seen the vertical mismatch problem that David started this thread about, I've never needed to compensate in the vertical plane (other than for a set of uneven Redfield-type bases I mentioned earlier, that problem being resolved with aluminum shims between the scope tube and ring). But another way to "fix" it would be to simply machine the ring clamp base above the clamp for the "high" dovetail a little shorter (deeper), thus allowing the clamps to reach a little deeper. There would be a practical limit to how much you could "gain" in this manner, but it would probably be sufficient to bring the mounts into reasonable alignment.

They are tapered for a reason -- to assure that the recoil of the rifle when fired tends to make the scope mounts/bases tighter rather than tend to loosen them. This is a clever system which is unique to Sako (a few other manufacturers used integral dovetails, but they utilized cross pins or other mechanisms to keep the scope from drifting forward under recoil.)

However, the tapering has one drawback: If the scope mount has one fixed claw (usually on the left side like Optilocks, Leupolds, etc.), then as the mount is positioned further forward on the dovetail the ring moves further to the left. If the front and rear rings are not positioned relatively close to the same place (fore and aft) on each dovetail, then the scope will point slightly left or right of the bore.

If in boresighting with the scope near its mid-range of adjustment the scope is pointing left, then this can be cured by either moving the rear ring forward or the front ring rearward (whichever is more practical). The opposite movement will compensate for a right-pointing scope.

In some applications, like a short scope on a long action, the latitude for movement of the rings may not be sufficient. If another type of ring which doesn't feature this problem (Millett, original Sako, Redfield, etc.) can't be substituted, then the proper ring (front or rear, according to which way the scope is off) can be modified with a three-corner file by slightly widening its clamp groove. This will have the same effect as "moving" that particular ring rearward, so be sure which way it is that you want your scope to move.

Having never seen the vertical mismatch problem that David started this thread about, I've never needed to compensate in the vertical plane (other than for a set of uneven Redfield-type bases I mentioned earlier, that problem being resolved with aluminum shims between the scope tube and ring). But another way to "fix" it would be to simply machine the ring clamp base above the clamp for the "high" dovetail a little shorter (deeper), thus allowing the clamps to reach a little deeper. There would be a practical limit to how much you could "gain" in this manner, but it would probably be sufficient to bring the mounts into reasonable alignment.